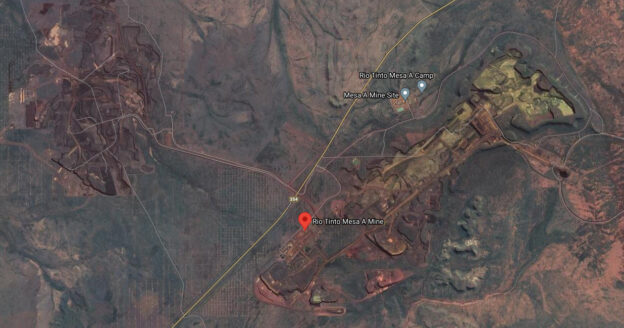

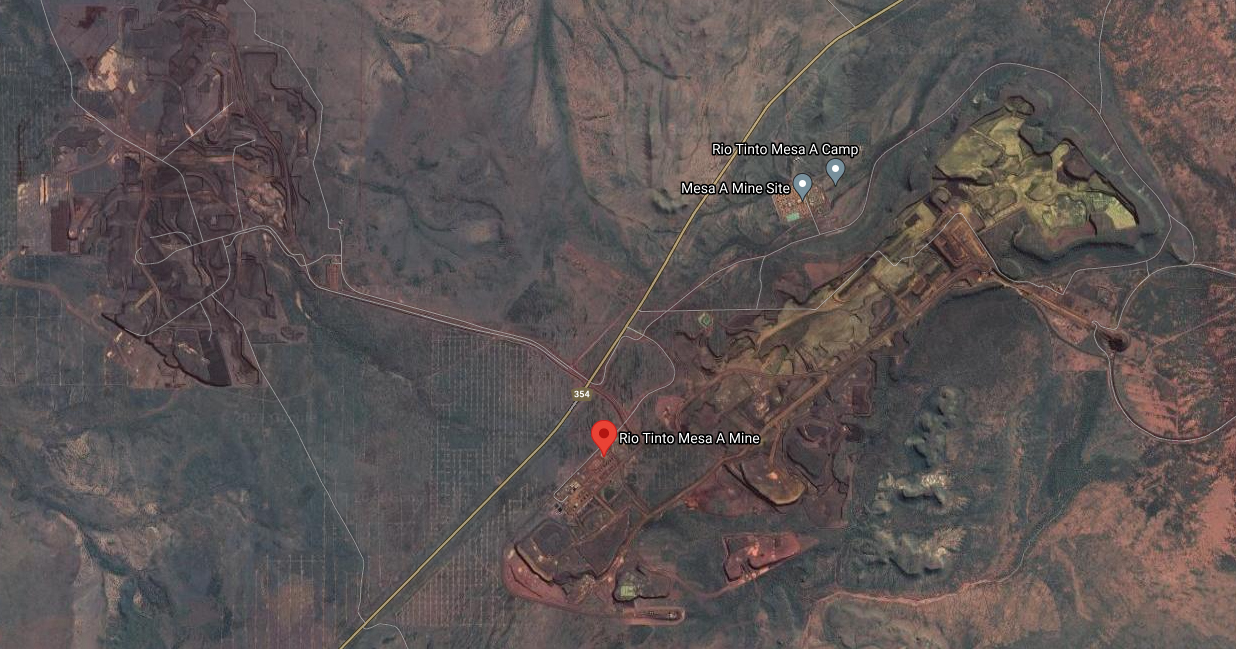

B&R has successfully supplied enclosures to Rio Tinto’s iron ore mine in Robe Valley, located within the Pilbara region of Western Australia.

B&R Enclosures received the work after Civmec Ltd, a construction and engineering services provider, was awarded a major contract with Rio Tinto to further develop its Mesa A operational hub in the Robe Valley.

BACKGROUND

B&R’s strong relationships within the mining sector led to securing business with Rio Tinto and Civmec.

Civmec engaged a local electrical wiring and equipment integrator to assist with the work. This integrator has a strong business relationship with B&R, and so the two companies worked collaboratively to supply the products to Civmec.

This project was part of Rio Tinto’s plan to sustain production capacity at its Robe Valley joint venture. This project includes developing three new mining deposits and the construction of supporting infrastructure needed for the continued operations within its two existing hubs at Mesa A and Mesa J.

THE CHALLENGE

Under the contract, B&R needed to supply a wide range of enclosures to cover several different applications including junction boxes, welding outlet boxes, and marshalling boxes. These applications were able to be covered with enclosures from the Pilbara SP, Finucane FI, Connector TE and TEMF product ranges.

B&R supplied the local electrical integration company with the required enclosures, who fitted the necessary switchgear and electrical equipment and installed the completed enclosure solutions under its Civmec contract, for end customer, Rio Tinto.

THE STRATEGY

Working closely with the Civmec and their chosen local integrator, B&R offered guidance on the correct part numbers to order, so the enclosures chosen were fit-for-purpose. This meant there weren’t any inefficiencies because the company didn’t waste time and money by swapping out enclosures due to miscalculations within the orders.

B&R also advised on which gland plates were suitable for which enclosures, based on application use and chosen enclosure material. Gland plates are used to protect electrical equipment inside the enclosures and uphold the IP (ingress protection) rating.

THE RESULT

All of the enclosures – which were to be used to house termination boards, junction boxes and control stations – were delivered, integrated, and installed in line with Rio Tinto’s work schedule .

To date, more than 400 enclosures have been supplied by B&R for the Robe Valley site, and B&R continues to receive orders for more enclosures, while carrying out ongoing maintenance work on the site.

CLIENT SATISFACTION

B&R’s enclosures are built to last and are constructed specifically for harsh Australian conditions, including high temperatures, the dusty outback, and salty seaside air.

Rio Tinto has been impressed with the high standard of B&R’s enclosures, specifically with their durability. This has led to ongoing work with Rio Tinto.